Resources

Resources

High-Power Laser Applications: Changing the World

Jun 13, 2023. Blog

Higher power laser use

During our childhood, we all have a period when we’re obsessed with lasers. Then, as we grow older, we get distracted by other aspects of our lives, and this fascination with lasers usually fades.

However, if we were to dig deeper into high-power laser applications, we would quickly realize that our world depends greatly on this crucial technology.

Everything from healthcare to high-precision manufacturing relies on lasers, and the impact of this technology on fields like nuclear physics, high-energy-density physics, and plasma physics might just shape our future. With that in mind, here’s how high-power lasers and their use are shaping the world we live in.

So, what is a high-power laser?

While there’s no exact threshold past which a laser becomes considered high-power, according to the consensus, high-power lasers have a continuous output in terawatts and even petawatts.

Now, even among high-power lasers, some are more advanced (and more potent). For instance, the high-repetition-rate advanced petawatt laser system (HAPLS) can drive laser-accelerated sources of electrons with energies of several tens of gigaelectronvolts, protons, and ions with energies reaching several megaelectronvolts. This means they can help make breakthroughs in nuclear physics, chemistry, biochemistry, x-ray radiography, and many other fields.

To further back up the full scale of applications for high-power lasers, one should just look at the number of universities and institutions that use them for anything from basic research to highly advanced applications.

With all of this in mind, here’s what lasers are used for today and what they might be used for in the future.

Manufacturing

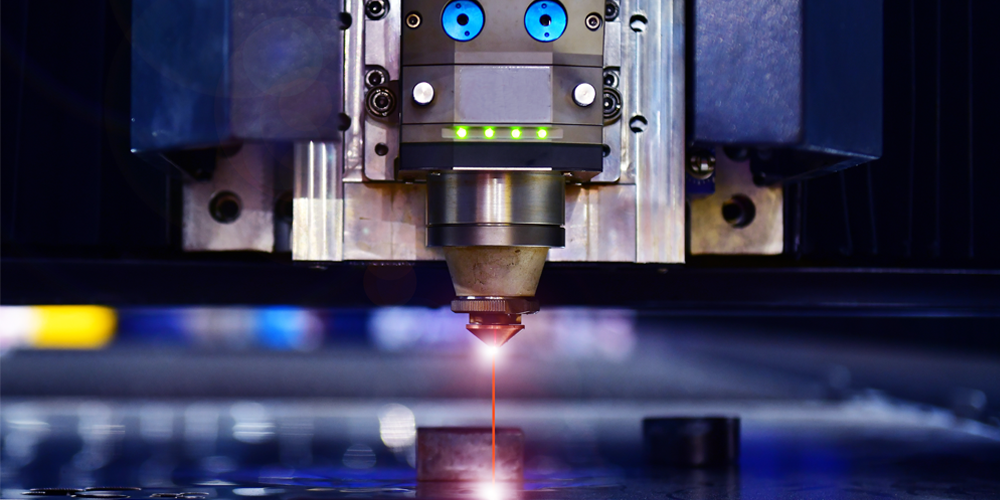

In the manufacturing industry, a high-power laser can be used for tasks from hardening and melting (for welding) to removing materials for drilling and cutting.

More commonly, high-power lasers are used for engraving. You can mark hard metals with lasers much faster and more precisely than any other method. This means you could process smaller and more intricate parts and do the work much faster than you would otherwise be capable of.

Another common application is laser cleaning. In the past, when the coating was applied selectively, you would have to mask parts that were not supposed to be coated and then coat everything else. This was an exceedingly time-consuming process. With laser cleaning, you can just coat the entire object and then remove the coating with the laser. This is only possible because cleaning is incredibly precise.

High precision machining

Still, the two most common uses of a laser in manufacturing are laser welding and laser cutting. Powerful enough to vaporize metal, these lasers are more precise than any similar tool. Some machines depend on fine contouring, and using a laser can drastically reduce the cycle time.

Some materials are even capable of non-thermal processing. This way, they use a short pulse method (shorter than ten picoseconds). By programming these pulse intervals, high-precision processing can be easy, safe, and automatic.

The most interesting thing about these lasers is their compact source. This means that the hardware is a lot smaller than you would expect it to be. As such, its industrial value is even higher.

Medical imaging

Amongst the uses of high-powered lasers, it’s important to stress the importance of medical imaging. This technology allows for high spatial resolution imaging. Moreover, the availability of wavelengths ranges from UV to Mid-IR, allows for higher precision and image resolution.

On top of this, the image generation and processing time are significantly shortened. When it comes to early cancer detection, this can be quite important.

When it comes to the growth of medical science, ultrashort femtosecond pulses can be used for real-time studies of molecular and sub-cellar dynamics. In other words, high-power laser applications range from highly pragmatic to uses in cutting-edge scientific research.

Medical procedures

You have probably heard about LASIK eye surgery. LASIK is short for laser-assisted in situ keratomileusis and is an effective alternative to wearing glasses or contact lenses. The success rate of this extremely effective surgery goes as high as 92%. More importantly, patients who undergo this surgery often report an improvement of up to 40% in their vision.

Fortunately, this is not the only example of the successful uses of laser technology in this field.

High-power laser therapy can also be used to:

- Remove tumors

- Prevent blood loss by sealing small blood vessels

- Treat skin conditions (removal of warts, moles, scars, and birthmarks)

Overall, while lasers are widely used for medical procedures (and in the medical field in general), we’re just tapping into the field of unlimited potential.

Semiconductor industry

Without semiconductors, there is no modern technology. Semiconductors are used in fields like:

- Communications

- Computing

- Healthcare

- Military system

- Transportation

- Clean energy

As well as in many other fields. The high-power laser applications in this industry are numerous and pivotal to the existence of this industry.

EUVL, or extreme ultraviolet lithography, is the most advanced form of semiconductor fabrication. It uses laser-pulsed droplet plasma in the manufacturing process.

Laser cutting is also one of the processes involved in wafer dicing. This is the process in which dies are separated from a semiconductor wafer. The automation of this process requires high precision and reliability of lasers.

Laser drilling allows the creation of holes with a diameter as small as 0.002”. While this is also useful in other fields, one should never underestimate the importance of this practice in semiconductor manufacturing.

Finally, the heat treatment process that changes the material’s physical properties (known as annealing) is commonly used to make the materials more workable. Even though this process was invented for metallurgical purposes, with the power of a laser, the use of this process in the semiconductor industry has become a common practice.

Wrap up

When it comes to the future, regardless of whether we’re talking about mining, medicine, or a rapidly growing semiconductor industry, it’s impossible not to think of lasers. However, many people are completely oblivious to the current rate of high-power laser applications. Still, it might not be long until their use is even more widespread.

So, join us at LaserNetUS to learn more about the applications and uses of high-power lasers.

More From Blog