Michigan Target Research and Fabrication (MiTRF)

Target Laboratory: assembly and component fabrication

- University of Michigan

The University of Michigan has the distinctive capability of fabricating targets for a wide variety of high-energy-density physics experiments. We have been assembling targets for OMEGA, JLF, Z, and several other facilities for over two decades. Our approach to a thoughtful and comprehensive fabrication process has been an endeavor to serve the broader HEDP community, such as those at National Laboratories, Universities, LaserNetUS and LLE PIs.

Capabilities

Overview

Equipment

On-site laser-cutter - We have a Keyence MD-U1000. This is a 355 nm, YVO4 laser, Class 4 Laser, 3 W/40 kHz (output at focal point: 2.5 W). This allows us to cut many different types of metals up to ~100 um thick and thicker plastics. There is a working area of 125 mm x 125 mm x 42 mm. We can adjust many parameters enabling us to cut a wide variety of materials and thicknesses. The laser spot size is 1 um, so we can do very small features into very small or larger parts.

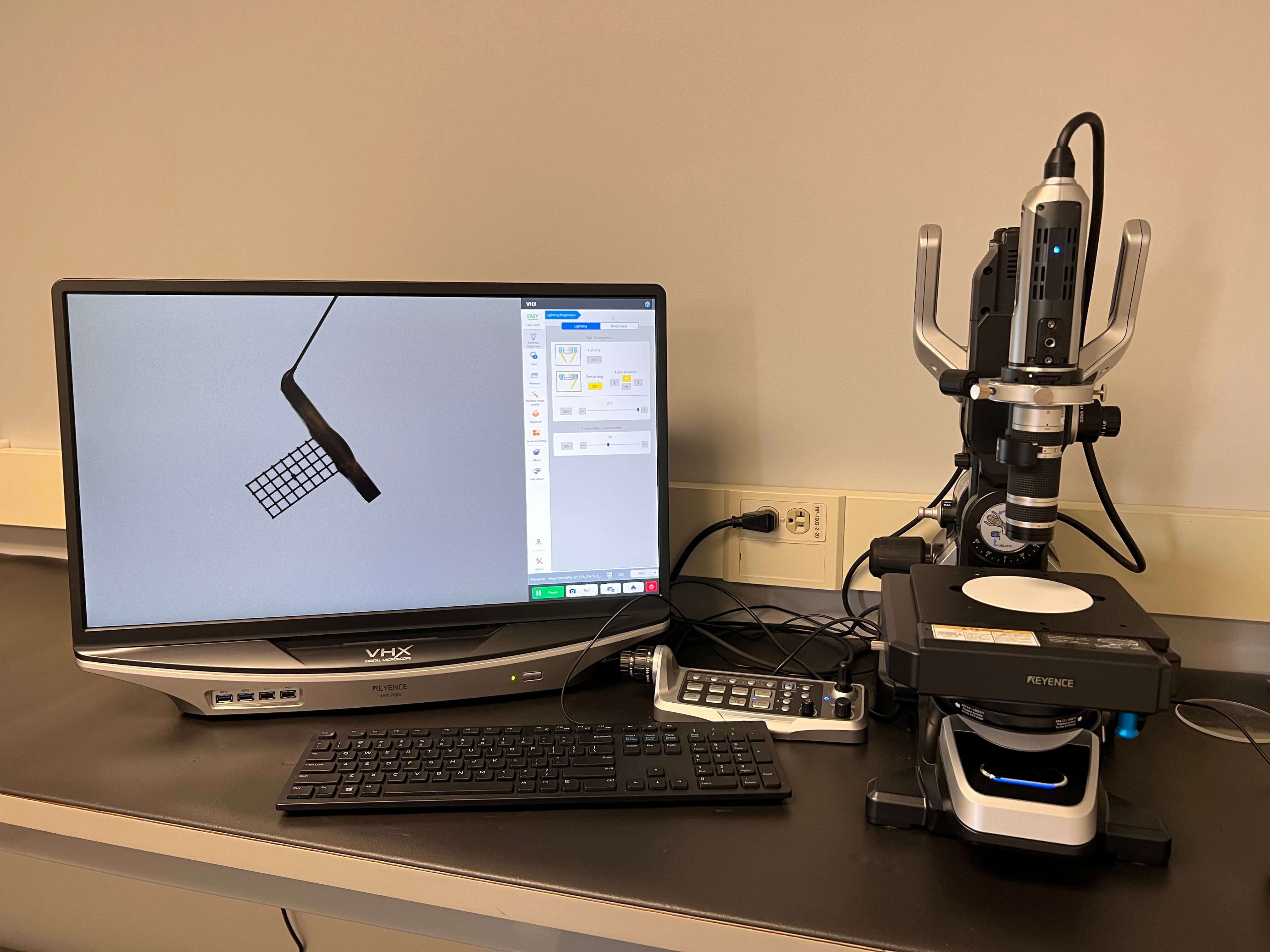

On-site digital microscope - We have a specialized microscope used for parts and assembly characterization. The Keyence-7000 has software that allows us to make precise measurements and capture images in great detail along with their measurements. It has 20x – 1000x magnification and 5 degrees of freedom to manipulate targets into many views. Targets and their components can be front lit or back lit to detect pinholes or measure features in fiducials best viewed monochromatically. This microscope also allows us to check our laser-cut parts for accuracy before they are assembled into finished targets.

PIs are provided with a comprehensive set of high resolution pictures of their components and/or targets with requested measurements.

Capabilities

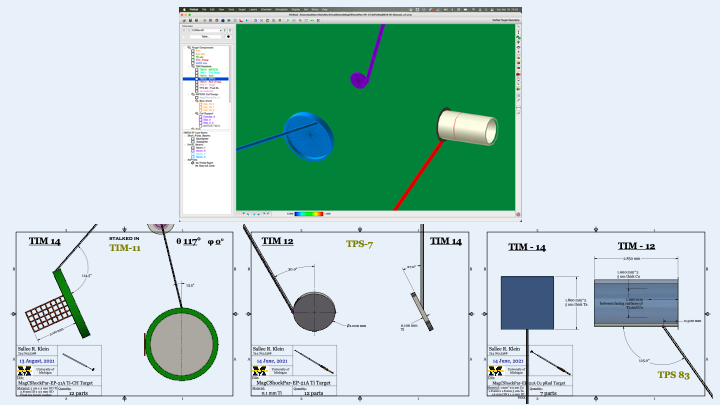

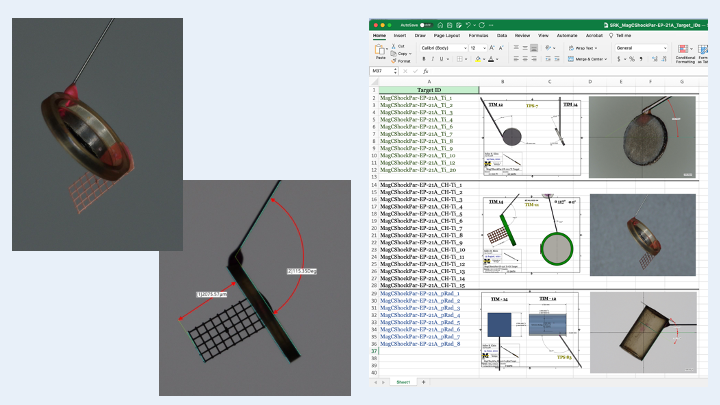

We are able to help with any or all aspects within a PI's target fabrication lifecycle. We can help with conceptual designs, such as utilizing a PI's simple sketches made in PowerPoint, or from Visrads by converting them into 3D CAD models, complete with drawings of all components and assemblies.

We provide comprehensive documentation of all parts characterization and target assembly metrology.

We store all unused targets and components in our Target Repository. We keep a detailed inventory of unshot targets and backlighters that PIs can use if/when needed. Targets are organized by PI affiliation and separated by campaign. They remain packaged and ready to deploy if/when needed.